Vibration control for machinery and plants: insulating foundation plinths.

Discover how to protect people, buildings and industrial processes with our vibration insulation solutions.

Why vibration control matters?

Machinery and plants generate dynamic forces that, without proper vibration damping, travel through the ground and into the structure—creating risks for people, as well as to the quality and continuity of production.

People

lower disturbance and better industrial soundproofing mean higher acoustic comfort and safety.

Machinery

reduced stress and wear lead to less maintenance and more stable overall equipment efficiency.

Building

mechanical protection for beams, columns and walls preserves long-term stability.

Process

a steadier environment supports repeatable, more efficient industrial production processes.

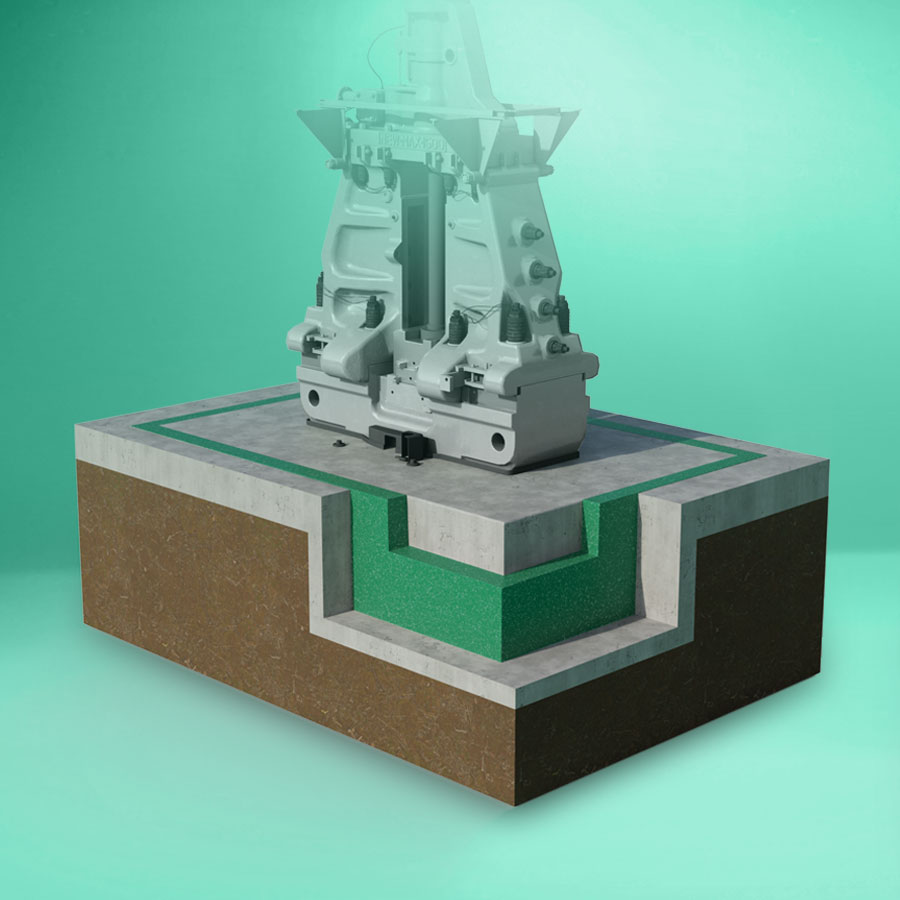

Insulating foundation plinths.

For heavy machines with triaxial movement, the most direct intervention is to insulate the bearing elements: creating insulated plinths that decouple the source from the structure.

What it solves

• Cuts transmission to floors, frames and neighbouring buildings.

• Stabilises the machine’s dynamic behaviour (cleaner, more consistent cycles).

• Lowers wear, vibration-related damage and maintenance costs.

• Improves industrial acoustic insulation and operator comfort.

Our solutions use high-performance elastomers, sized to actual load and operating frequencies, for durable, effective vibration damping.

When insulated plinths are the right choice.

Presses, moulding lines, high-mass machine tools; compressors, pumps and chillers; test benches and precision lines; plants with frequent starts/stops and dynamic peaks.

If the machine rests on discrete supports or dedicated bases, plinth insulation is often the most efficient route. In other cases we assess inertial bases insulation, direct machinery insulation, on-board insulation or insulation for the whole production facility, depending on the specific context and requirements.

How it works (in short).

Between the plinth and sub-base we install a custom elastomeric package. This layer acts like a controlled spring: it filters critical frequencies, damps vibration and limits the flow of dynamic energy. The result is twofold: better machine soundproofing to the outside and quieter, safer, more stable conditions inside the facility.

Key benefits.

Source-focused

control.

Operational stability and better cycle quality.

Less wear, fewer unplanned stops.

Higher acoustic comfort for operators.

Mechanical protection for the structure.

Lower operating costs, greater continuity.

Design criteria that make the difference.

• Static/dynamic loads (mass, fixings).

• Operating and excitation frequency spectra (avoid resonance).

• Soil and structural conditions (propagation, constraints, proximity).

• Plant layout (avoid rigid bridges via pipes and cable trays).

• System durability/easy maintainability.

From data to solution: our method for insulted plinths.

We analyse loads and frequencies, model the response, select the elastomer and size the system; then we manage installation and interfaces to prevent rigid connections and verify the dynamic response at commissioning. That’s how we combine vibration insulation, industrial soundproofing and mechanical protection—with measurable gains in quality, maintenance and productivity.