Under-screed acoustic insulation: stop impact noise.

How to choose the right under-screed insulator and design an effective, durable, easy-to-install build-up.

Why intervene under the screed?

Steps, knocks and dragging generate vibrations and noise that travel through the structure. Adding an elastic layer under the screed creates a controlled decoupling between screed and slab. The result is immediate: less noise reaching the floor below, greater privacy, higher comfort and structural protection.

The three main solutions?

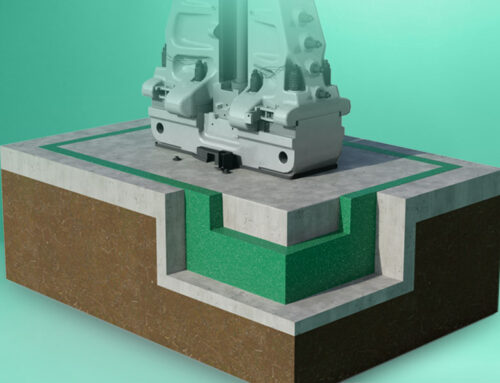

Traditional under-screed system

The go-to choice when thickness isn’t an issue. It ensures excellent reduction of footfall noise and a straightforward installation.

Low-thickness under-screed system

Ideal for refurbishments or wherever finished floor levels are constrained. Top performance in just a few millimetres.

Dry under-screed system

For fast-track sites or where wet trades must be minimised: quick, predictable installation without compromising performance.

How to choose the under-screed insulator.

Loads and intended use

determine the most suitable elastic stiffness of the underlay.

Available thickness

guides the choice between traditional, low-thickness or dry solutions.

Acoustic goal

how much do you want to reduce footfall noise for the space below? The clearer the target, the more effective the design.

Compatibility with radiant heating

continuous bearing, stability over time.

Installation details

continuous layer, correct joints, perimeter strips to avoid acoustic bridges.

Durability

performance that remains stable under load and over lifecycle.

Benefits that matter.

Concrete reduction

of footfall and impact noise (steps, drops, dragging).

Higher comfort

and perceived quality in homes, offices and retail.

Versatility

new builds and refurbishments, including low-thickness and dry systems.

Long-term reliability

thanks to stable materials and correct installation.

Why choose Isolgomma.

For over 50 years we’ve been designing tailor-made under-screed solutions. We support designers and contractors in selecting the most suitable under-screed acoustic underlay and we take care of the application details to ensure real-world performance. Sustainability, high-performance recycled materials and a technical team by your side: that’s how we turn every floor into a quiet, reliable and durable system.