Technical area

Our resources at your service.

Thanks to the expertise of our engineers and their considerable experience in vibration control in the rail transport sector, we are able to offer you a range of exclusive and highly professional services. This allows us to accompany you through every stage of the project: from defining the most suitable solution to choosing the product, from installation to correct laying, right through to on-site checks.

Consulting.

Our technical department can provide you with all the technical advice you need to develop your anti-vibration project. We can also provide specific support for local maintenance work: this way, we help you find the ideal solution to ensure rapid completion with very short intervention times.

Research into guided tracks.

In Italy, we are leaders in the study and production of vibration reduction systems for the rail transport sector.

At Isolgomma, our R&D centre develops products with a constant monitoring system for production processes, effectively and rigorously following ISO 9000 procedures. Thanks to this important “Product Study” facility, we are able to develop new items and technologies in an extremely short time.

Our laboratory.

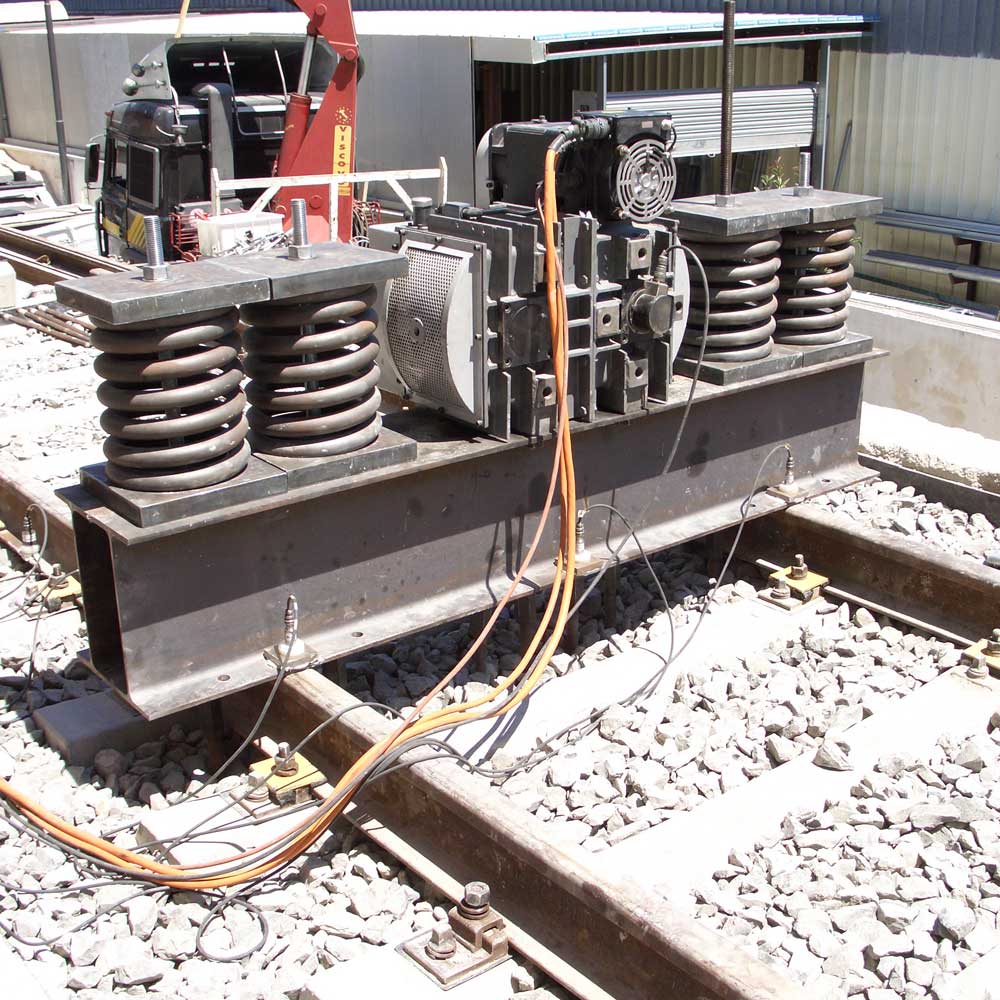

“The main activity of our Laboratory is to perform tests to characterise the mechanical properties, performance, fatigue and accelerated ageing of anti-vibration mats.

Our centre is equipped with a Resilient Pad and Mat Testing Machine (RPMTM) designed to perform static and dynamic tests up to 100Hz on mats and plates. We also have a railway test track where two full-scale prototypes of railway and tram/underground track systems have been built, designed to perform static and dynamic tests using hydraulic pistons and vibrodynes.”

Research and development.

The collaboration between our R&D centre in Pozzuoli and the University of Naples has enabled us to achieve and maintain the highest quality standards for our products over time, as well as certifications and technical documentation regarding surface, tunnel and underground railway applications.